Concebido para Aumentar a Eficiência da Extrusão de Metal.

Every extrusion company is looking to eliminate costly prototypes and reduce redesign cycles. Now advanced physics simulations are accessible to organizations of all sizes. Altair Inspire Extrude Metal is an easy-to-learn tool that enables simulation to be used by any engineer or designer to increase their understanding of how profile features and process variables interact for any particular metal alloy. It will help your team achieve productivity gains by reducing product development costs and improve extrusion quality, increasing production yield and customer satisfaction.

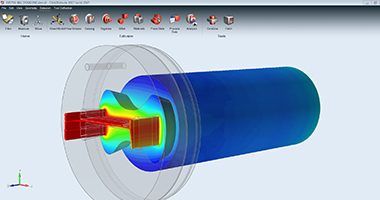

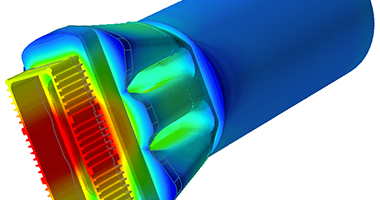

Make better design decisions by detecting potential defects before a die is built. Even the most complex profiles can be validated for production with Inspire Extrude Metal. Using the geometry creation and simplification tools, CAD can be quickly de-featured and modified inside the tool, ensuring potential profile distortion, damage from deflection, backend contamination, charge weld defects, bad seam weld, bad grain size, overheating profile quality, and poor surface quality issues are corrected early in development.

Lower scrap rates can be achieved by exploring process improvements on a virtual press. Simulation allows you to see inside your production line and fine-tune process variables to reduce visible and invisible defects. Inspire Extrude Metal provides quick studies of extrusion die performance, an understanding of profile deformation, visualization of temperatures in the part, modeling of the elastic and elasto-plastic properties of the tool assembly, correcting die using automatic bearing optimization, predictions of quenching rates.

Módulo Eficiente e Orientado a Processos

Quick and easy to learn. After only a few hours of standard training new users are confidently working with Altair Inspire Extrude Metal.

Obtenção do Design Optimizado de Matrizes e Peças

Save time and costly die rework with virtual die trials with Altair Inspire Extrude Metal to produce quality-assured, complex shaped extruded products.

Redução dos Custo de Fabrico

Applying Altair Inspire Extrude Metal simulation starting at the concept design phase avoids costly prototyping of competing concepts, redesigns and retooling: all before the die is manufactured.

Características Principais

Criação e Simplificação de Geometrias

Correct, modify, and de-feature solid models using Altair Inspire Extrude Metal’s modeling tools.

Um Software de Fácil Aprendizagem

The intuitive, process-driven user experience enables users to gain deep manufacturing insights quickly, driving faster and better design decisions.

Análise de Extrusão

Investigate extrusion die performance, visualize profile deformation, temperature in extruded part, elastic and elastoplastic analysis on tool assembly, perform quenching analysis.

Opções de Optimização

Automatically optimize bearing length with Altair Inspire Extrude Metal to avoid expensive die rework.

Evite Defeitos

Easily predict and plot all common extrusion defects: distortion, backend contamination, charge weld defects, seam welds, bad grain size, overheating, die wear, poor surface quality.

Personalização de Materiais

Select from aluminum, steel, magnesium, and titanium alloys in Altair Inspire Extrude Metal's material library or create Custom materials.

Histórias de Sucesso

Apel Extrusions

Interessado em testar as soluções Althima?

Solicite o acesso a uma avaliação gratuita de 15.

(sujeita a apreciação interna)

A nossa equipa encontra-se preparar para qualquer questão.

Diga-nos como o podemos ajudar.